| Application |

Transparence

Crystal clear mounts good for specimens with pores, voids or empty spaces. Can be used in a mixed mount as an insulator for electrolytical preparation or as a backfill for labelling.

|

Fast

Fastest hot mounting resin on the market. Best suited for soft materials or as "backing" for other resins when speed is of essence.

|

Conductive

Conductive resin relevant when electrolytical polishing and etching is used.

|

SEM analysis

Carbon filler enables SEM examination & offers very low shrinkage + high removal rate.

|

Edge retention

Superior edge-retention for hard & medium hard materials with very low risk of gaps.

|

Edge retention

Excellent edge-retention for medium hard & soft materials with very low risk of gaps.

|

Dust-free

No health hazards & dust free. Recommended for soft to medium hard materials.

|

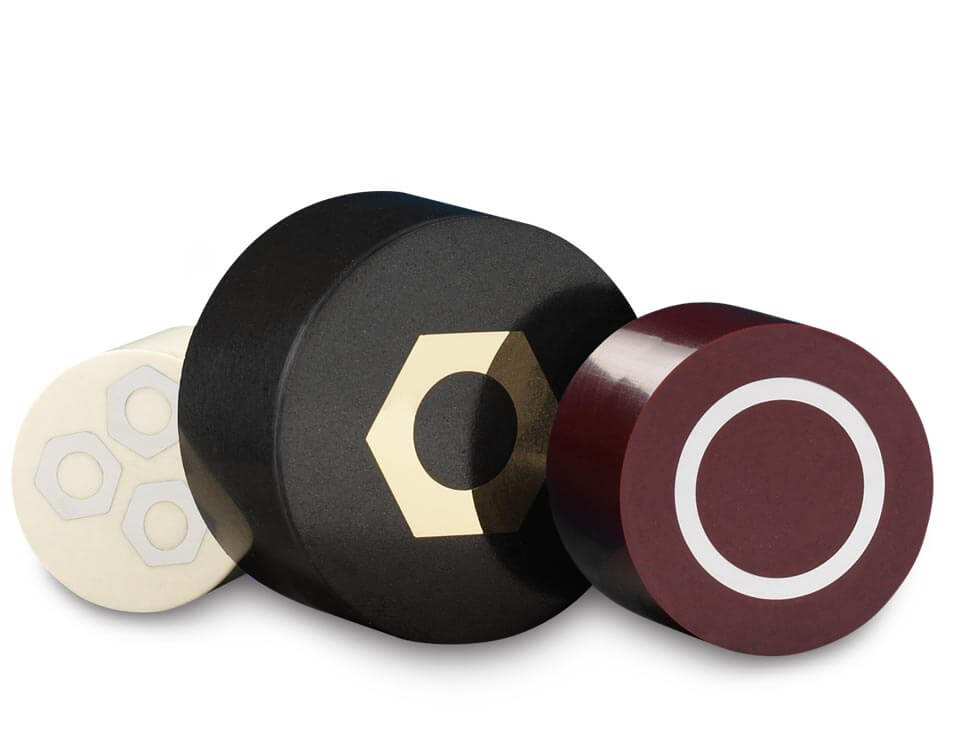

Routine

Bakelite type resin for routine examination of soft to medium hard materials, or as backfill. Three colors available.

|