Magnutom-5000

- Intuitive icon-based programming

- Simulator function

- AxioWash automatic cleaning

- Automatic X and Rotary tables

- Rotary movement

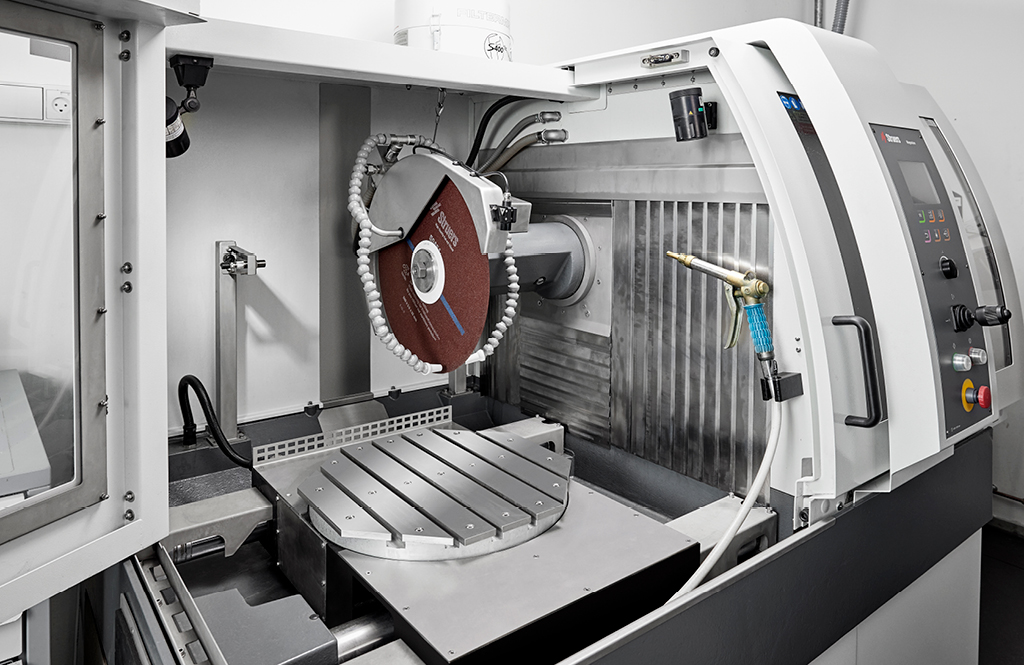

As the only cut-off machine in its field, Magnutom-5000 can map out the most complex of section sequences and simulate all individual sections for you to validate. Magnutom-5000 is the largest machine in its field with four automated axes, as well as a rotary table, which enables a large variety of sectioning possibilities. The spacious 1000 mm wide cutting chamber and sliding front door make it possible to use a forklift or crane to load heavy samples.

Get the cut right the first time with simulator

As the only cut-off machine in its field, Magnutom-5000 can map out the most complex of section sequences and then, with the patent pending simulator function, simulate all individual sections for you to correct or validate before sectioning. No time or materials are wasted on trial sections.

All movements are easily operated with the joystick. By integrating the movement of the joystick, the laser light and the software features, Magnutom-5000 presents a unique user interface. During programing, the joystick is moved to the sectioning points and the exact position is logged into the sequence. The operator only needs to decide whether to move or cut.

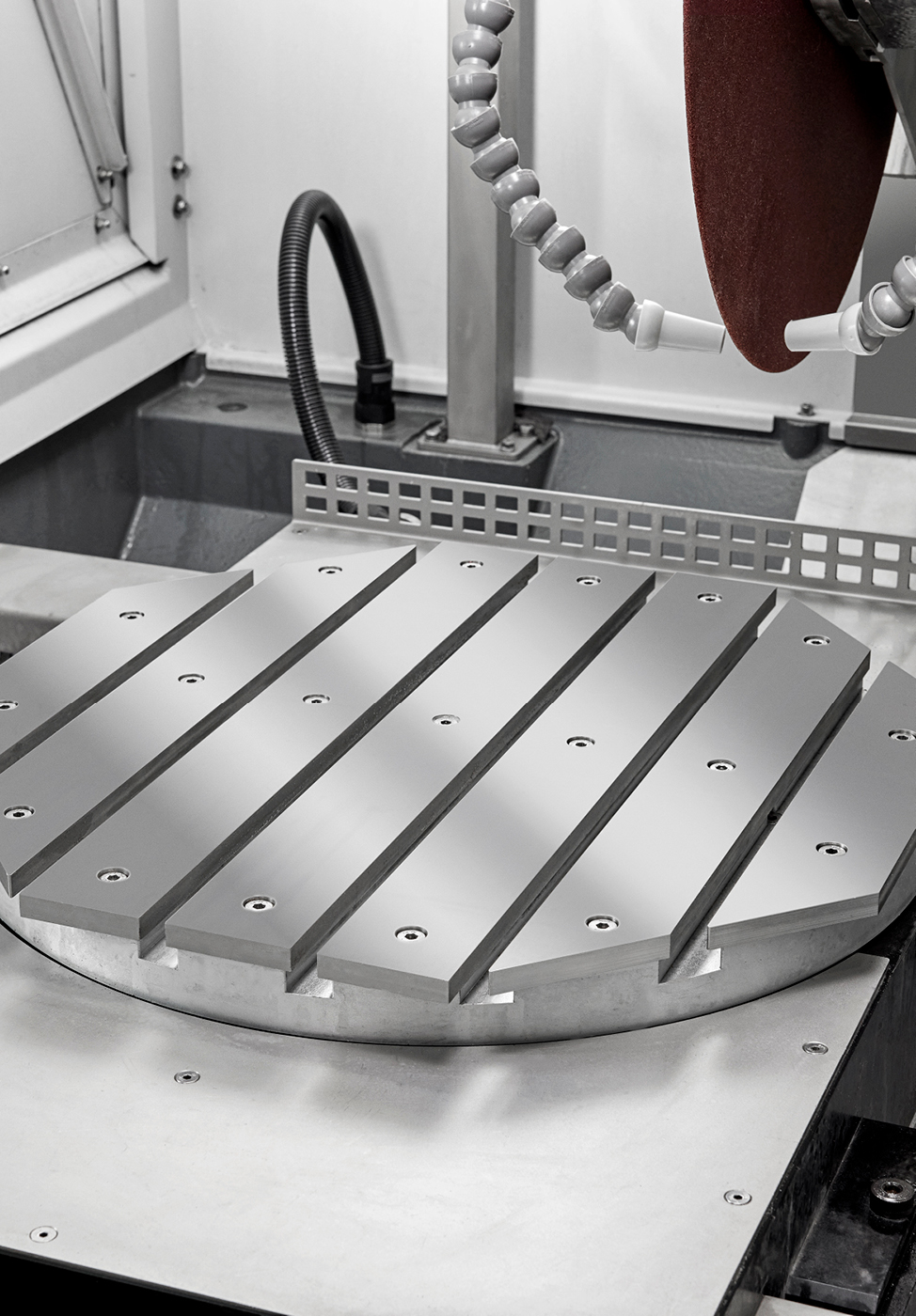

Automated rotary table supersedes re-clamping

A section is only as accurate as the quality of the clamping. The Magnutom-5000 is the largest machine in its field with four automated axes, including a rotary table. Imagine how much time can be saved with no re-clamping.

Sectioning in up to 4 axes in fully automatic sequences makes it possible to carry out a series of parallel or angled sections of the same or varying thicknesses. Magnutom-5000 has safe move settings, which prevent damage and cut-off wheel breakages during movement.

Save consumables with automatic rpm-compensation

Magnutom-5000 adapts its speed automatically via rpm-optimization as the cut-off wheel wears down. This means 31% more sections per cut-off wheel can be produced in certain situations by using Struers’ specialized consumables.

Struers’ cut-off wheels have a composition which partially compensates for wear, and on the Magnutom-5000 XYZ and XYZR models, built-in sensors will monitor the wear of the cut-off wheel. The information feeds into algorithms on the machine, and by increasing the speed it insures increased yield of the cut-off wheel.

Key features that save you time and let you cut to the point

-

Spindle lock makes it faster and easier to change cut-off wheels

The spindle lock makes it faster and easier to change cut-off wheels. The spindle lock does not depend on a certain position of the cut-off wheel. By the push of a button, the operator locks the position of the spindle in any position.

Spindle lock makes it faster and easier to change cut-off wheels

-

User-friendly joystick enables fast and easy programming

Discover fast and easy programming with the user-friendly joystick. All movements are easily controlled with the joystick. Simply move the cut-off wheel in position and make the cut. When more positions are combined into a cutting sequence, the positions are easily captured and logged in programming by the touch of a button. The intuitive operation of the machine only requires basic training.

User-friendly joystick enables fast and easy programming

-

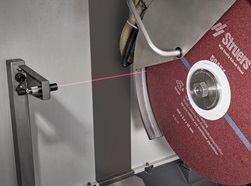

Laser light points out the precise position for your section

Laser light points out the precise position for your section. Clamping and positioning of the workpiece can be tedious and time-demanding. The laser is a greatly helpful tool and used in combination with the joystick it makes positioning much more convenient. The laser indicates the left edge of the cut-off wheel. In the simulator function, the laser light will indicate where the cuts are positioned before even making one cut.

Laser light points out the precise position for your section

-

Faster programming with icon-based user interface

With the intuitive, icon-based user interface, you will get programming done in no time and reproduce the same accuracy in hundreds or even thousands of sections.

Faster programming with icon-based user interface

-

Three table variants enable clamping for any need

Magnutom-5000 comes with three table variants that enable clamping for any need – automatic XY-table with rotary movement, automatic XY-table with X-movement and fixed table.

Three table variants enable clamping for any need

-

Hinge side door that opens up completely for optimal access

The hinged sliding front door that opens wide and the spacious 1000 mm wide cutting chamber gives you unrestricted access and make it possible to use a forklift or crane to load heavy samples.

Hinge side door that opens up completely for optimal access

-

Cut-off wheel monitoring helps you save consumables

Magnutom-5000 adapts speed automatically via rpm-optimization as the cut-off wheel wears down. This means 31% more sections per cut-off wheel in certain situations by using Struers’ specialized consumables.

Cut-off wheel monitoring helps you save consumables

-

AxioWash automatic cleaning with Struers’ patented cleaning program

AxioWash is Struers’ patented cleaning program, which can be used every day to keep the machine in optimal working condition.

AxioWash automatic cleaning with Struers’ patented cleaning program

-

Powerful water pistol for easy and effective manual cleaning of the cutting chamber

Water pistol featuring an adjustable water flow mechanism for efficient and easy manual cleaning, complemented by an extended-length hose for full access to all areas within the cutting chamber.

Powerful water pistol for easy and effective manual cleaning of the cutting chamber

-

Flexible and easy-to-use clamping tools for fast and stable fixation of your workpiece

A wide array of versatile, easy-to-use clamping tools accommodates both regular and irregular workpieces of any size, ensuring adequate stability and easy repeatability.

Flexible and easy-to-use clamping tools for fast and stable fixation of your workpiece

Facts

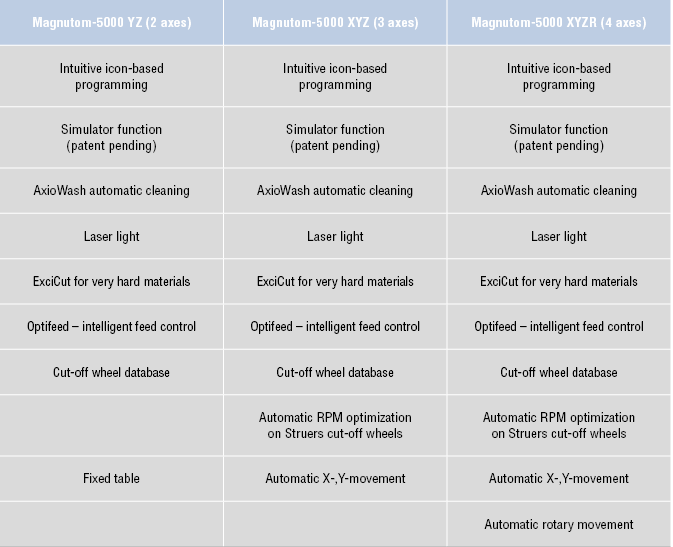

Model types

Magnutom-5000 is available in three versions. See specifications for details.

With key features such as intuitive icon-based programming, simulator function, AxioWash automatic cleaning, laser light and fixed table.

Magnutom-5000 XYZ (3 axes)

With key features such as intuitive icon-based programming, simulator function, AxioWash automatic cleaning, laser light, automatic X-table, automatic Y-movement, X-movement and automatic RPM optimization on Struers cut-off wheels.

Magnutom-5000 XYZR (4 axes)

With key features such as intuitive icon-based programming, simulator function, AxioWash automatic cleaning, laser light, automatic X-table, automatic Y-movement, rotary movement and automatic RPM optimization on Struers cut-off wheels.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Get your Technical Data Sheet for Magnutom-5000

A short and clear description that gives you an immediate overview to help you make the best choice of equipment.

• Capacity and performance specifications

• Dimensions and weight

• Electrical data

• Noice levels

• Safety

Get your brochure for Magnutom-5000

Get the full introduction, descriptive visuals, and key feature descriptions to help you qualify your choice of equipment.

• Explanatory photos

• Key feature descriptions

• Technical Data Sheet

Cutting consumables

-

Abrasive cut-off wheels

Extremely hard ferrous metal (500 < HV < 1400).

Go to webshop Contact sales -

Abrasive cut-off wheels

Very hard ferrous metal (400 < HV < 800).

Go to webshop Contact sales -

Abrasive cut-off wheels

Hard Ferrous metal (275 < HV < 750).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium hard ferrous metal (200 < HV < 550).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium soft ferrous metal (100 < HV < 500).

Go to webshop Contact sales -

Abrasive cut-off wheels

Soft ferrous metal (75 < HV < 375).

Go to webshop Contact sales -

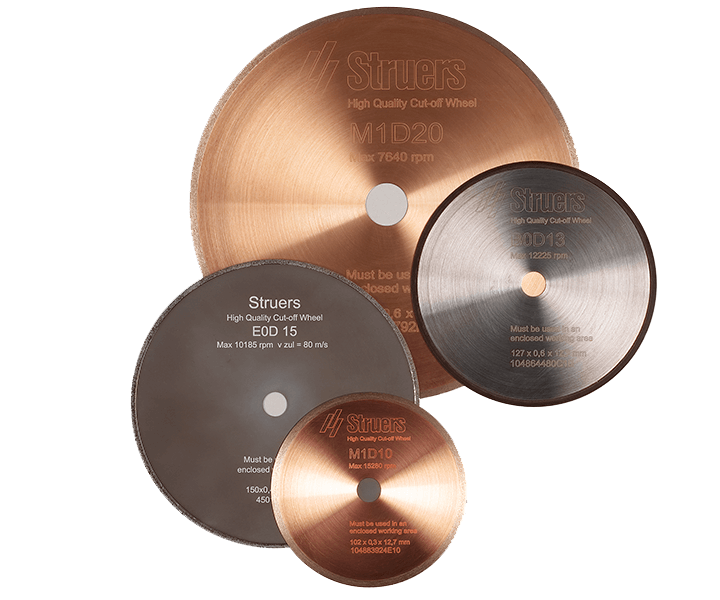

Diamond cut-off wheels

For materials with HV 500-2400.

Go to webshop Contact sales -

CBN cut-off wheels

For materials with HV 500-2400.

Go to webshop -

Additives for cutting

For recirculation, cooling and cleaning.

Go to webshop Contact sales -

+

-

−

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab