HOW CAN OUR OXIDE POLISHING SUSPENSIONS SUPPORT YOUR MATERIALOGRAPHIC PROCESS?

Improve your verification process

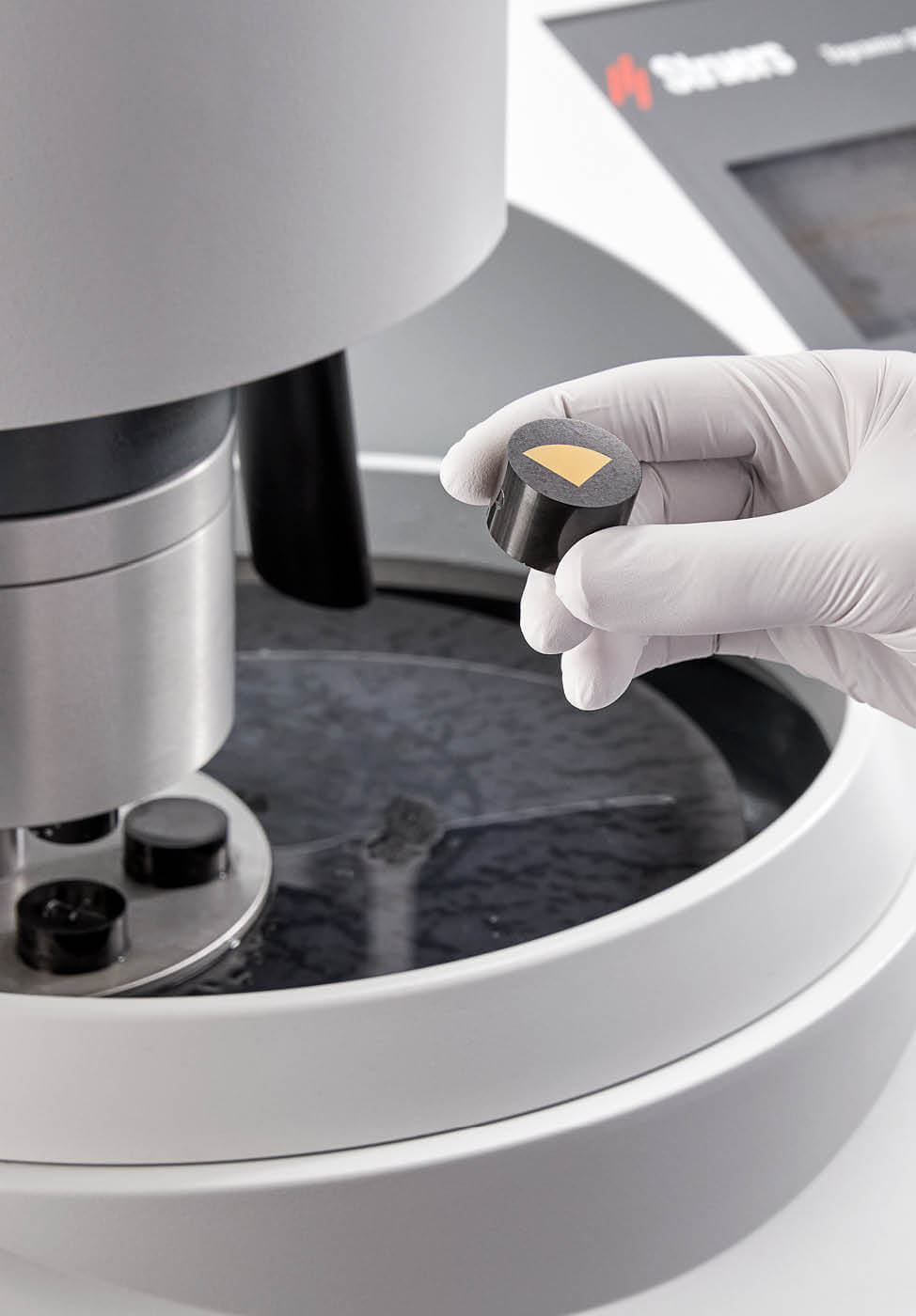

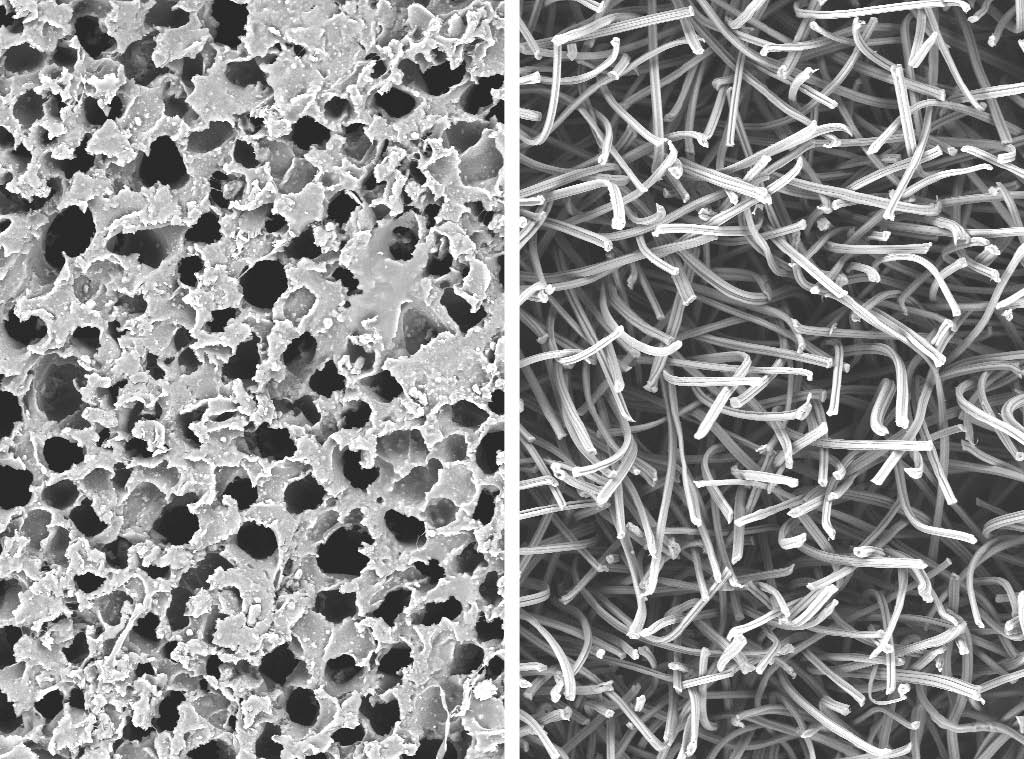

You need a perfect surface finish for verification, for example using electron microscopy. Our Oxide Polishing Suspensions remove absolutely all scratches and deformation, giving you complete trust in your verification step.

Prepare mechanical resistant materials with ease

You work with extremely hard, soft, or ductile materials that are resistant to mechanical preparation. They therefore require a chemical-mechanical step in order to remove all scratches and deformation. We have an Oxide Polishing Suspension optimized for every material type, giving you a perfect surface finish with zero compromise on speed.

Minimize your risk of process interruptions

If you have an automated lab set-up, avoiding process stops are a priority. Our NonDry Oxide Polishing Suspensions prevent costly interruptions and delays by ensuring that dosing tubes do not clog up. They also reduce the possibility of crystals from the suspension becoming embedded in polishing cloths, reducing the risk of scratches or having to repeat process steps.