AbraPlan-30 facts

- Ultra-fast for up to 90% faster plane grinding

- High-capacity, and controlled material removal

- Powerful performance, with exceptional stability

- Excellent versatility with grinding stones and diamond discs for all materials

- Automatic dressing for constant speed and efficiency

- Ideal for plane grinding of multiple, large or very hard materials

- Minimal training required

The strongest dedicated high-speed plane grinding machine on the market, AbraPlan is ideal for high throughput labs that need fast and controlled material removal . A versatile semi-automatic solution, it delivers fast and accurate results on multiple, large and very hard materials. Using dedicated high-speed plane grinding stones or diamond discs, AbraPlan will optimize your throughput.

For best throughput results, AbraPlan is designed to work with AbraPol.

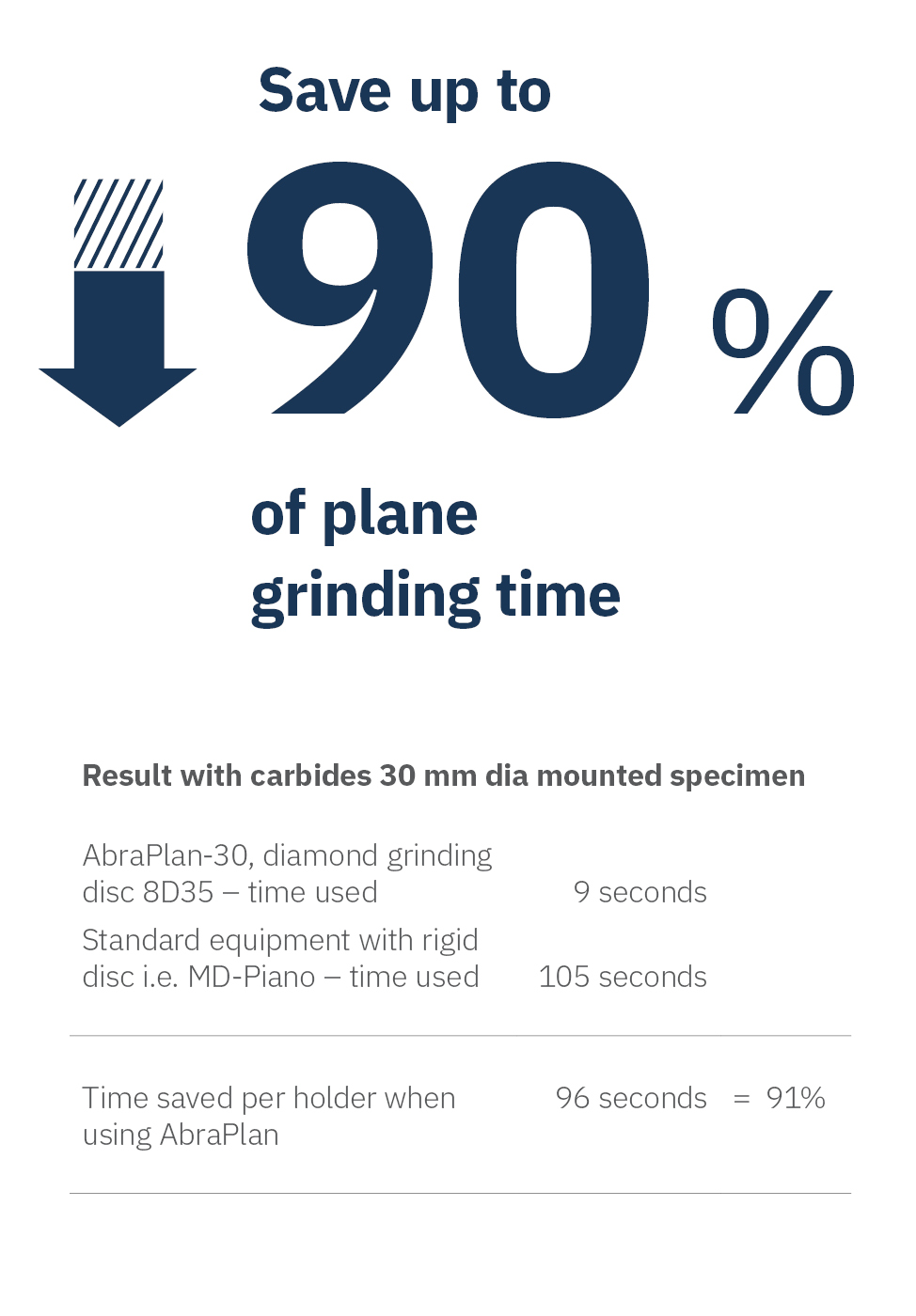

Ultra-fast for up to 90% faster plane grinding

If you need high throughput and have limited time , AbraPlan is your best choice for plane grinding. When used with Struers’ grinding stones and diamond discs, AbraPlan can reduce your grinding times by up to 90% compared to plane grinding on MD surfaces (such as silicon carbide foils, papers, or rigid discs). Simply put: AbraPlan is the fastest heavy-duty grinding solution available.

Fast and controlled material removal

AbraPlan’s grinding surface rotates at 1,450 rpm, ensuring very high material removal. An accurate material removal sensor (from 0.05 mm to 10 mm) allows you to pre-set the amount of material to be removed, making it ideal for high throughput labs where speed and short turnaround times are required.

Powerful performance

AbraPlan is exceptionally stable and robust, with an extremely solid frame and powerful grinding motors. The design limits vibrations, even when plane grinding at high speeds and forces. It has a stainless steel bowl, with a lifetime corrosion warranty, to limit damage if a specimen comes loose from the specimen mover.

KEY FEATURES THAT ENSURE FAST AND EFFICIENT, HIGH-VOLUME, AND TROUBLE-FREE GRINDING

-

Automatic dressing for constant removal

The automatic diamond dresser keeps the grinding stone plane and sharp for optimum performance and precise results. The performance of the grinding stone is monitored continuously and, as soon as removal drops below a pre-defined level, the stone is dressed. This guarantees consistent high-speed performance and the perfect surface quality of specimens. In addition, optimized dressing parameters reduce stone wear by more than 60 % to lower your consumables costs.

Automatic dressing for constant removal

-

Controlled material removal for a faster process

AbraPlan delivers unmatched specimen planeness and reproducibility, which will save you time on subsequent fine grinding or polishing steps.

The grinding stone rotates at 1,450 rpm, ensuring very high material removal. The accurate material removal sensor allows you to pre-set the amount of material to be removed, from 0.05 mm to 10.00 mm at increments of 10 μm. A high-quality surface finish is typically achieved in 20-30 seconds. This ensures you only remove the necessary material, saving you time in the next process step.Controlled material removal for a faster process

-

Removal rate graph to optimize your process

The removal rate graph shows the material removal rate on the sample, as well as when the stone is dressed. This makes it possible to establish optimal dressing parameters to increase efficiency and reduce stone consumption. When working with manual dressing, the removal rate graph indicates when it is time to dress the stone.

In addition, the dresser automatically monitors the remaining thickness of the grinding stone at start-up and informs you when it needs to be replaced.Removal rate graph to optimize your process

-

Improved accuracy function with low tolerances

AbraPlan’s Improved accuracy function improves grinding precision to save you time on the next step.

Deflection from pressing the specimen holder against the stone can reduce accuracy when working with low tolerances. With the Improved accuracy function, the 0-point for the removal measurement is taken before grinding starts (when the stone is not rotating). This makes removal measurement more accurate.Improved accuracy function with low tolerances

-

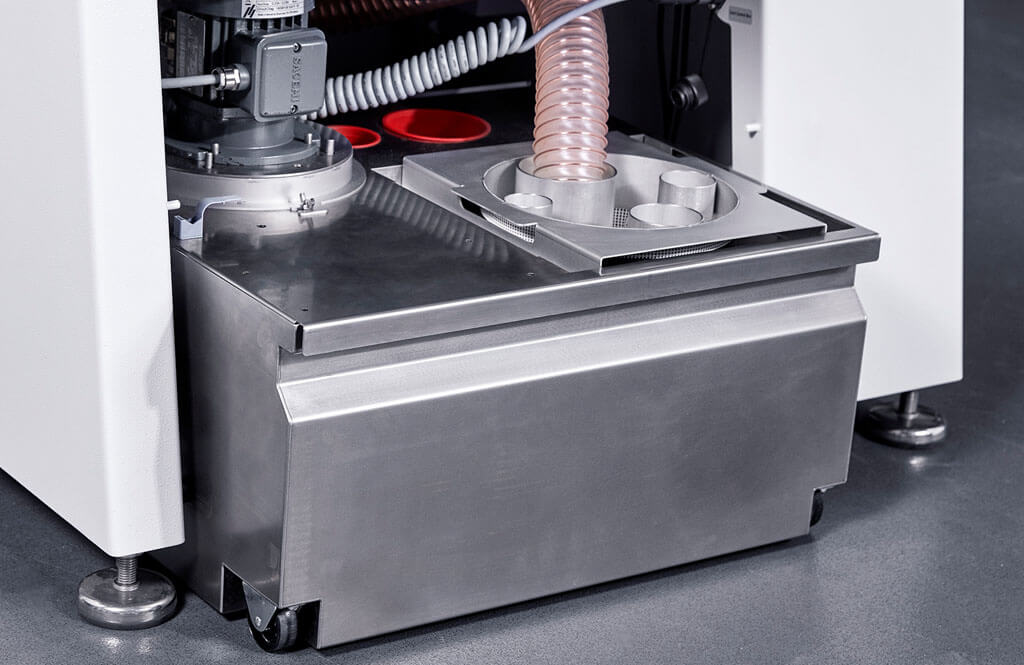

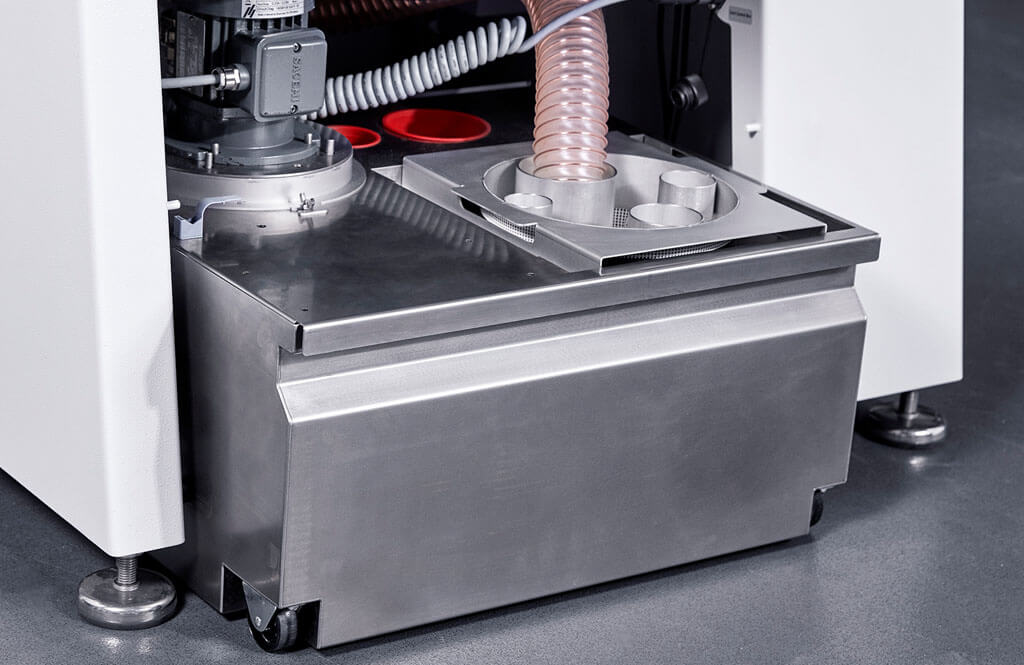

Stainless steel bowl for improved lifetime

Made from high-quality stainless steel, AbraPlan’s bowl is less likely to be damaged if a specimen is lost at high speed, reducing maintenance requirements and increasing safety. The bowl comes with a lifetime corrosion warranty on breakthrough corrosion.

Stainless steel bowl for improved lifetime

-

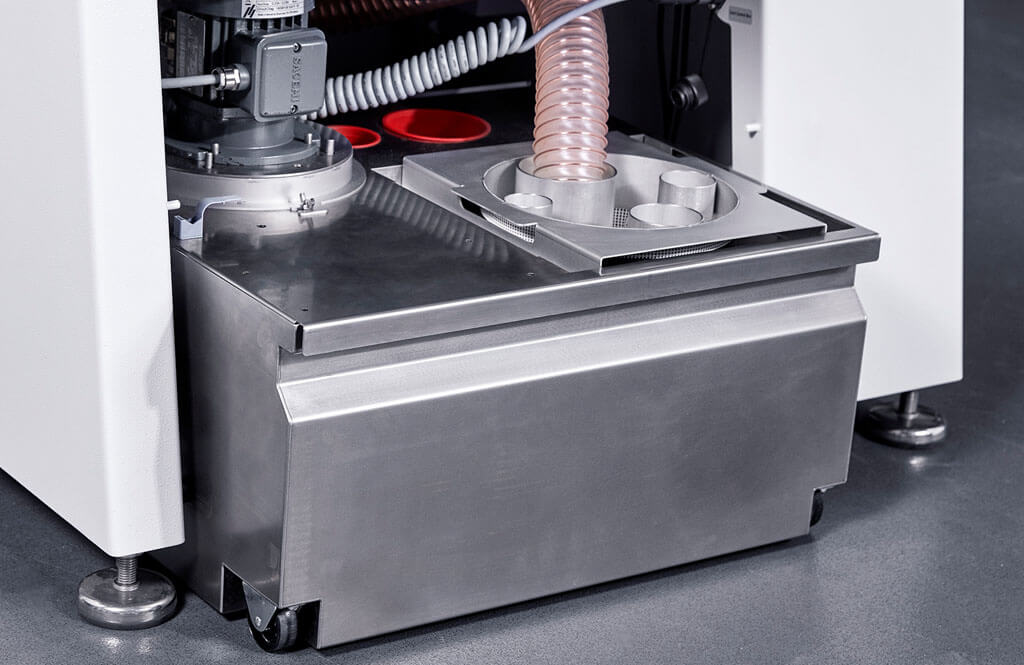

Recirculation unit for cost-efficient water use

Cooling water minimizes heat when grinding. The AbraPlan’s integrated recirculation cooling water unit ensures cost-efficient water utilization and collects removed abrasives to lower your water consumption and reduce the amount of classified products spent.

The unit is easy to access for maintenance and cooling water control. For improved safety, the three-phase recirculation pump is connected directly to the AbraPlan machine to ensure the emergency stop also stops the recirculation pump.Recirculation unit for cost-efficient water use

-

Grinding stones and diamond discs for any material

For ultra-fast plane grinding, our grinding stones and diamond grinding discs are optimized to provide high, consistent removal with low deformation. This reduces time spent on the fine grinding step, as well as your overall preparation time. In tests, our stones have an average removal rate of 474 μm/min. They can be used to plane grind large specimens, or multiple small specimens at once.

Different types of materials require different types of grinding surfaces. To ensure high versatility, we have developed a variety of grinding stones and diamond discs covering a wide range of materials. These include aluminum oxide and silicon carbide stones for normal steels, hardened steels, and soft and ductile materials. For extremely hard materials, such as sintered carbides or ceramics, we supply a diamond grinding disc. For more information, please see our Grinding consumables brochure.

We keep grinding stones in stock to ensure short delivery times to your lab.Grinding stones and diamond discs for any material

-

Diamond grinding disc for hard/brittle materials

Plane grinding of very hard and brittle materials, such as tungsten and sintered carbides, can take a long time. It also wears the grinding surface much faster than other materials. Using a diamond grinding disc on the AbraPlan significantly reduces the time it takes to grind very hard and brittle materials – while also lowering your consumables costs.

Diamond grinding disc for hard/brittle materials

-

Flushing gun for easy cleaning

To ensure a long lifetime, we recommend keeping the AbraPlan clean through frequent cleaning and maintenance. A built-in flushing gun makes cleaning of the grinding area fast and easy, using recirculation water directly from the machine.

Flushing gun for easy cleaning

-

Non-clogging outlet stops blockages

The AbraPlan has a large (50 mm/2" diameter) outlet and a drain tube with a smooth inner surface to ensure that grinding water does not clog the bowl. The bowl’s outlet can easily be cleaned using a brush or ‘bottle-brush’ without pushing the drain tube away from the outlet.

Non-clogging outlet stops blockages

-

Maximum operator safety

AbraPlan is designed with the highest level of operator safety in mind. The grinding stone and specimen holder are completely encapsulated in stainless steel covers, eliminating the risk of incorrectly clamped specimens flying out. The entire working area is encapsulated by a transparent safety cover, preventing accidental access to rotating parts. The machine cannot be started before the safety cover is closed and the safety cover can only be opened when the machine is stopped.

Maximum operator safety

-

User-friendly interface for minimal training

AbraPlan is very easy to operate with minimal training. The large display and icons give the operator a clear overview of process parameters. The stone icon makes it simple to see the stone’s status (dressed or used). The multipurpose turn/push knob makes navigation easy. The countdown feature allows the operator to see the remaining grinding time or remaining material to be removed.

User-friendly interface for minimal training

-

Beacon for monitoring from across the lab

The colored beacon on AbraPlan enables the operator to monitor the machine’s operating state from a distance. The different colored lamps on the beacon can be set up individually to give the operator specific status information as required.

Beacon for monitoring from across the lab

Facts

Find the right accessories for your AbraPlan

Increase the efficiency of your process and improve the reliability of your result with our grinding and polishing accessories. We offer a full range of specimen holders, mover plates, leveling devices, and preparation discs.

Download our accessories overview sheetModel types

AbraPlan-30

AbraPlan-30

Advanced semi-automatic machine for plane grinding of specimens in specimen holders up to 200 mm/8” dia. AbraPlan-30 features an automatic diamond dresser with automatic surface detection, a removal rate sensor, and a transparent safety cover. Recirculation cooling tank, pump and filter, grinding stones, and specimen holders are available separately.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards. Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Technical Data

AbraPlan-30 Technical Data Sheet

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download technical data sheetPerfectly reproducible

Download our grinding and polishing brochure to get a full overview of our grinding & polishing equipment.

Download the brochureFind the right accessories for your AbraPlan

Increase the efficiency of your process and improve the reliability of your result with our grinding and polishing accessories. We offer a full range of specimen holders, mover plates, leveling devices, and preparation discs.

Download our accessories overview sheetGrinding stones and diamond grinding discs

-

Grinding stones and discs

For high removal grinding with low deformation

Read more Contact sales -

−

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer

Contact us!

370, rue du Marché Rollay

94507 Champigny sur Marne cedex

France