Unique functionalities for superior results

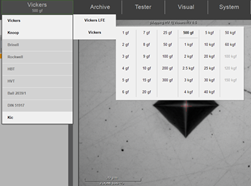

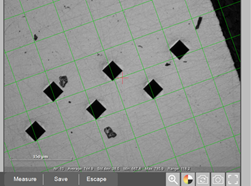

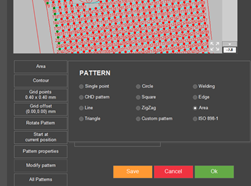

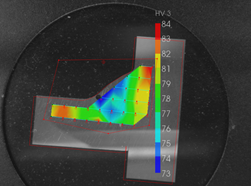

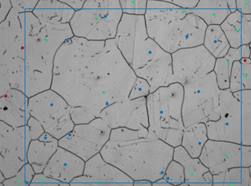

Use the overview camera for fast positioning of the pre-programmed patterns and let the DuraVista do all indent and measurement work unattended. Higher and more reliable throughput without the need to hire more lab staff.

Built for your Business

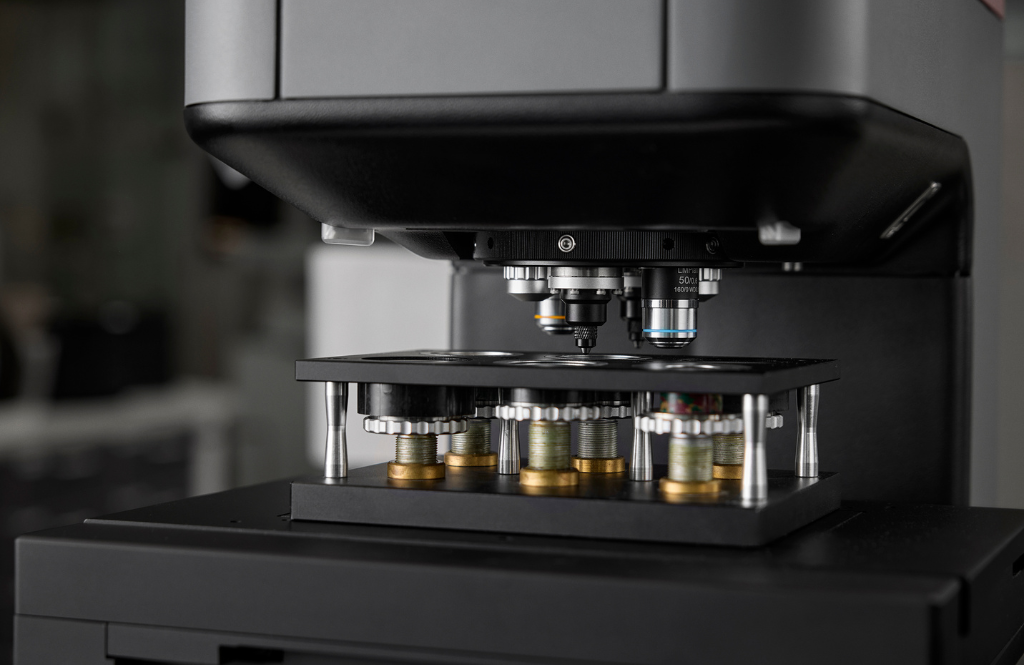

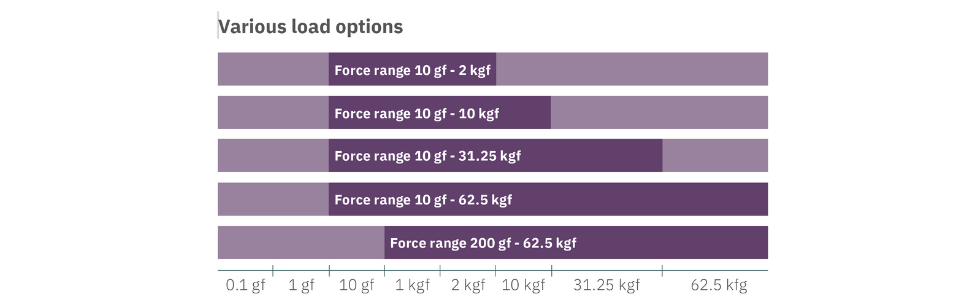

Both hard- and software were designed to comply with ISO and ASTM standards fully from the load mechanics, the optical system, and the high-resolution camera to the advanced software algorithms. The Z-axis is controlled with a precision ball screw spindle for a fast and precise movement for focus and positioning. Unique in its class.

The future is automated

Today, automation is widely accepted as THE solution for consistency and quality. DuraVista-40 with a closed-loop cell improves for process accuracy and limits the risk of human influence. Manage all machine control and workflow processes effortlessly using the 27” industrial capacitive touchscreen. Start multiple jobs at once and focus on other duties while the DuraVista-40 handles all the indent-measure work for you.